120 Ton Hydraulic Iron Worker Punching Machine

Price 1595000 INR/ Piece

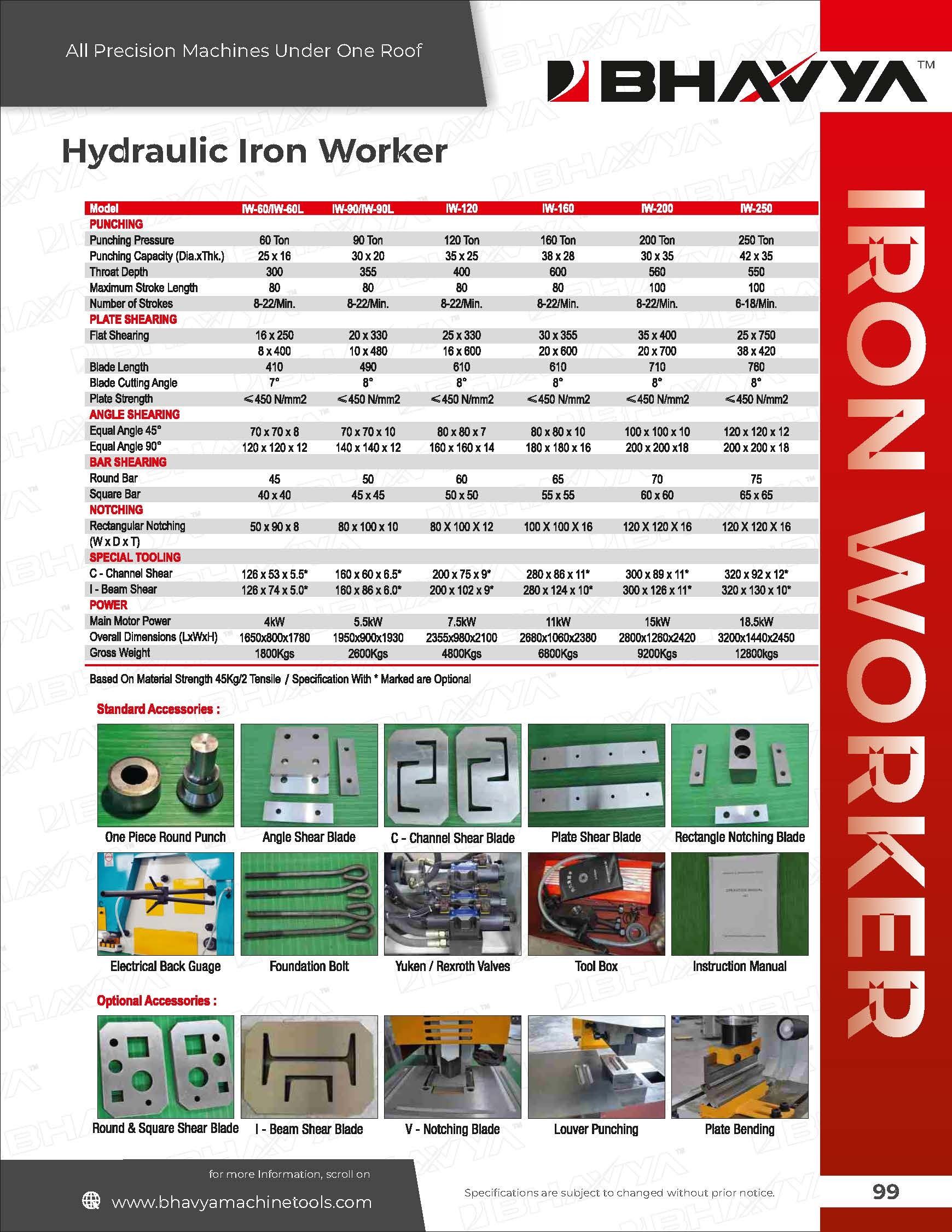

120 Ton Hydraulic Iron Worker Punching Machine Specification

- Country Of Origin

- Made in India

- Frequency

- 50 Hertz (HZ)

- Control System

- Semi-Automatic

- Voltage

- 220-440 Volt (v)

- Features

- Strong build, Low maintenance cost, Highly efficient and effective

- Product Type

- Milling Machine

- Power Source

- Electricity

- Operating Type

- Automatic

- Surface Treatment

- Painted

- Warranty

- 12 Months

- Usage & Applications

- Industrial

About 120 Ton Hydraulic Iron Worker Punching Machine

FAQ :

A: This machine is made from the finest grade iron and is coated with a corrosion-resistant finish.

Q: What is the power source of this machine?

A: This machine is powered by hydraulic power source.

Q: What are the applications of this machine?

A: This machine is ideal for industrial applications and is used for punching, shearing, notching and bending.

Q: Is this machine easy to operate and maintain?

A: Yes, this machine is easy to operate and maintain.

Q: What is the price of this machine?

A: We offer this machine at the best price. Please contact us for more information.

|

Condition |

New |

|

Quality |

High |

|

Physical Form |

Solid |

|

Product Type |

Hydraulic Iron Worker Punching Machine |

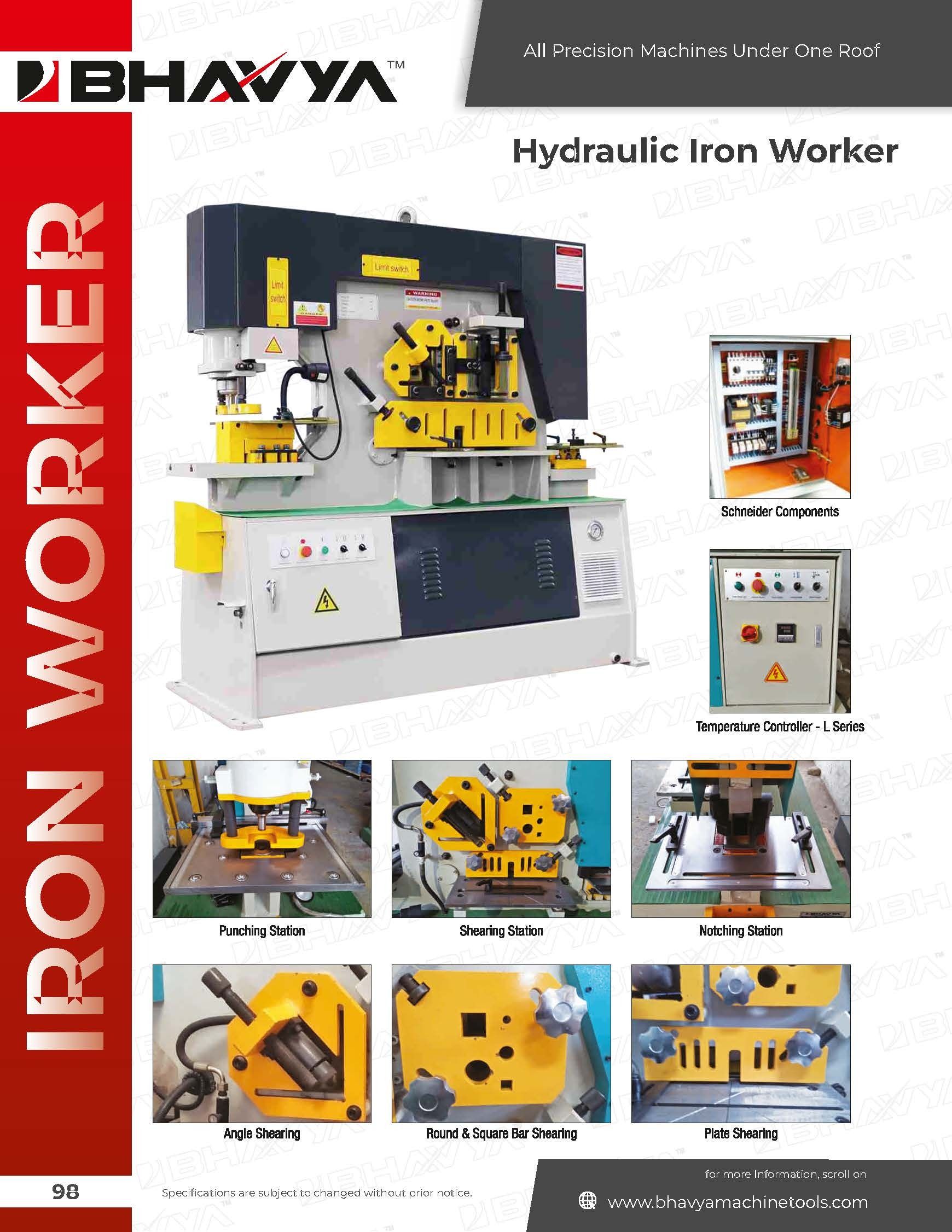

Effortless Industrial Productivity

This 120 Ton Hydraulic Iron Worker Punching Machine offers seamless operation to meet the rigorous demands of industrial environments. Its automatic functionality and robust build make it a reliable choice for cutting, punching, and shaping metal with consistent precision, helping businesses streamline production and reduce manual labor.

Durable Design & Reliable Performance

Engineered with a quality painted surface treatment, the machine resists corrosion and wear, extending its operational lifespan. With a comprehensive 12-month warranty, users have peace of mind, knowing ongoing support is readily available directly from the Indian manufacturer and supplier.

FAQ's of 120 Ton Hydraulic Iron Worker Punching Machine:

Q: How does the automatic operation of the 120 Ton Hydraulic Iron Worker enhance industrial efficiency?

A: The machine's automatic operating mode allows for faster and more precise metalwork processes compared to manual methods. This reduces labor costs and increases production speed, making it especially beneficial for high-volume industrial applications.Q: What types of applications is this punching machine best suited for?

A: This hydraulic iron worker is designed for a wide range of industrial tasks, including punching, bending, shearing, and notching metals. It is ideal for fabrication shops, construction projects, and manufacturing plants requiring robust and consistent metal processing.Q: When should the machine be serviced to ensure optimal performance?

A: Regular maintenance should be conducted according to the manufacturer's guidelines, typically every few months depending on usage intensity. Routine checks help in maintaining efficiency and prolonging the lifespan of the equipment.Q: Where can I purchase genuine spare parts or get support for this machine in India?

A: Genuine spare parts and after-sales support are available directly from the manufacturer and supplier in India, ensuring you have reliable access to necessary components and technical assistance.Q: What is the process for installing this hydraulic iron worker at an industrial site?

A: Installation is carried out by qualified technicians provided by the manufacturer or supplier. The process involves positioning, electrical hookup, and initial calibration to ensure the machine operates safely and correctly from the outset.Q: How does the painted surface treatment benefit the machine's longevity?

A: The painted surface acts as a protective layer against rust, corrosion, and wear, which are common in heavy-duty industrial settings. This treatment extends the machine's service life and reduces the need for frequent maintenance or repairs.Q: What key benefits does the 12-month warranty offer to users?

A: The 12-month warranty covers manufacturing defects and assures users of prompt repair or replacement if issues arise within the covered period, offering peace of mind and minimizing downtime for businesses.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Punching Machine Category

Hydraulic Iron Worker Punching Machine

Price 854000 INR / Unit

Minimum Order Quantity : 1 Unit

Power Source : Hydraulic

Features : Strong build, Low maintenance cost, Highly efficient and effective

Voltage : 220440 Volt (v)

Control System : SemiAutomatic

Hydraulic Angle Notcher Punching Machine

Price 554500.00 INR / Unit

Minimum Order Quantity : 1 Unit

Power Source : Hydraulic

Features : Strong build, Low maintenance cost, Highly efficient and effective

Voltage : 220440 Volt (v)

Control System : SemiAutomatic

160 Ton Hydraulic Iron Worker Punching Machine

Price 2250000 INR / Unit

Minimum Order Quantity : 1 Unit

Power Source : Electricity

Features : Strong build, Low maintenance cost, Highly efficient and effective

Voltage : 220440 Volt (v)

Control System : SemiAutomatic

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS