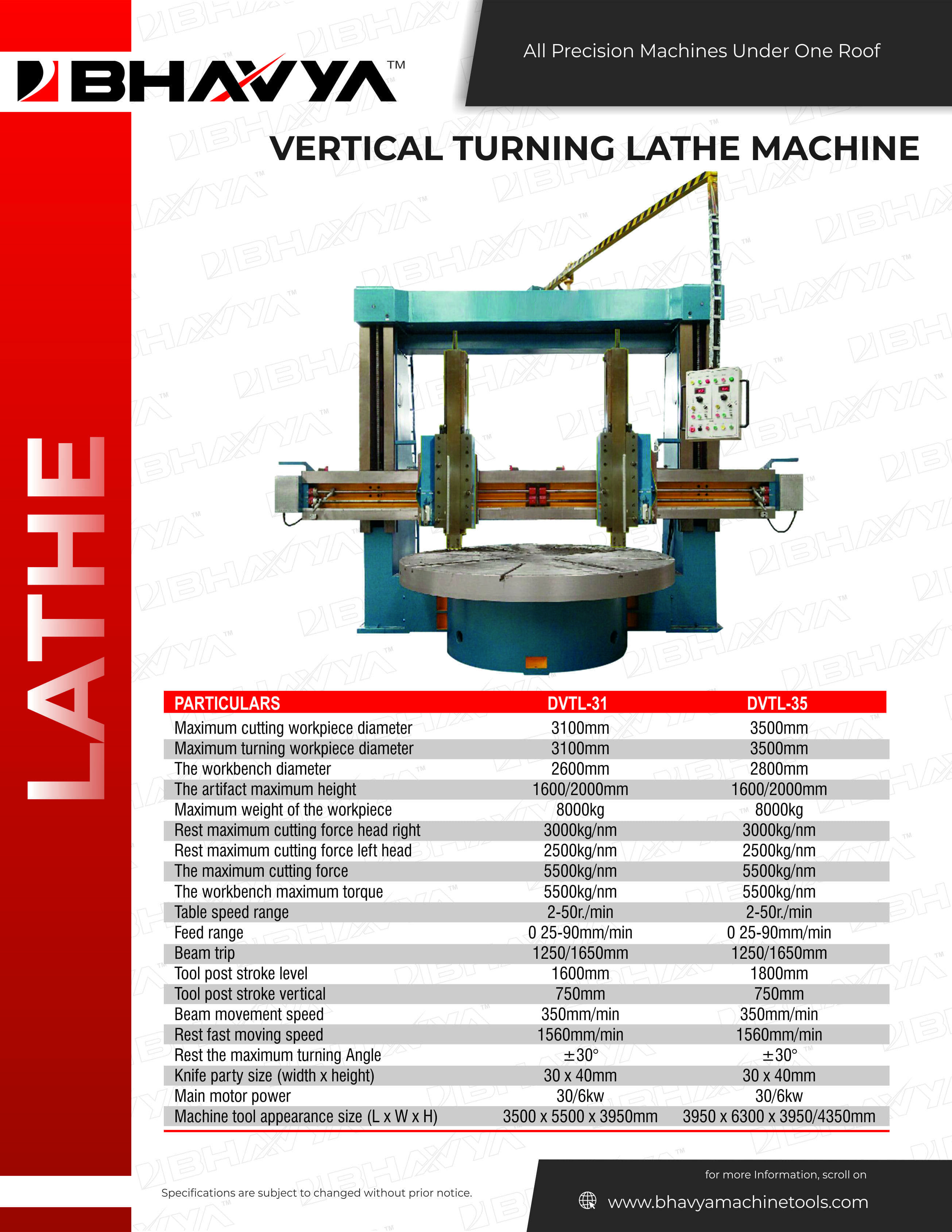

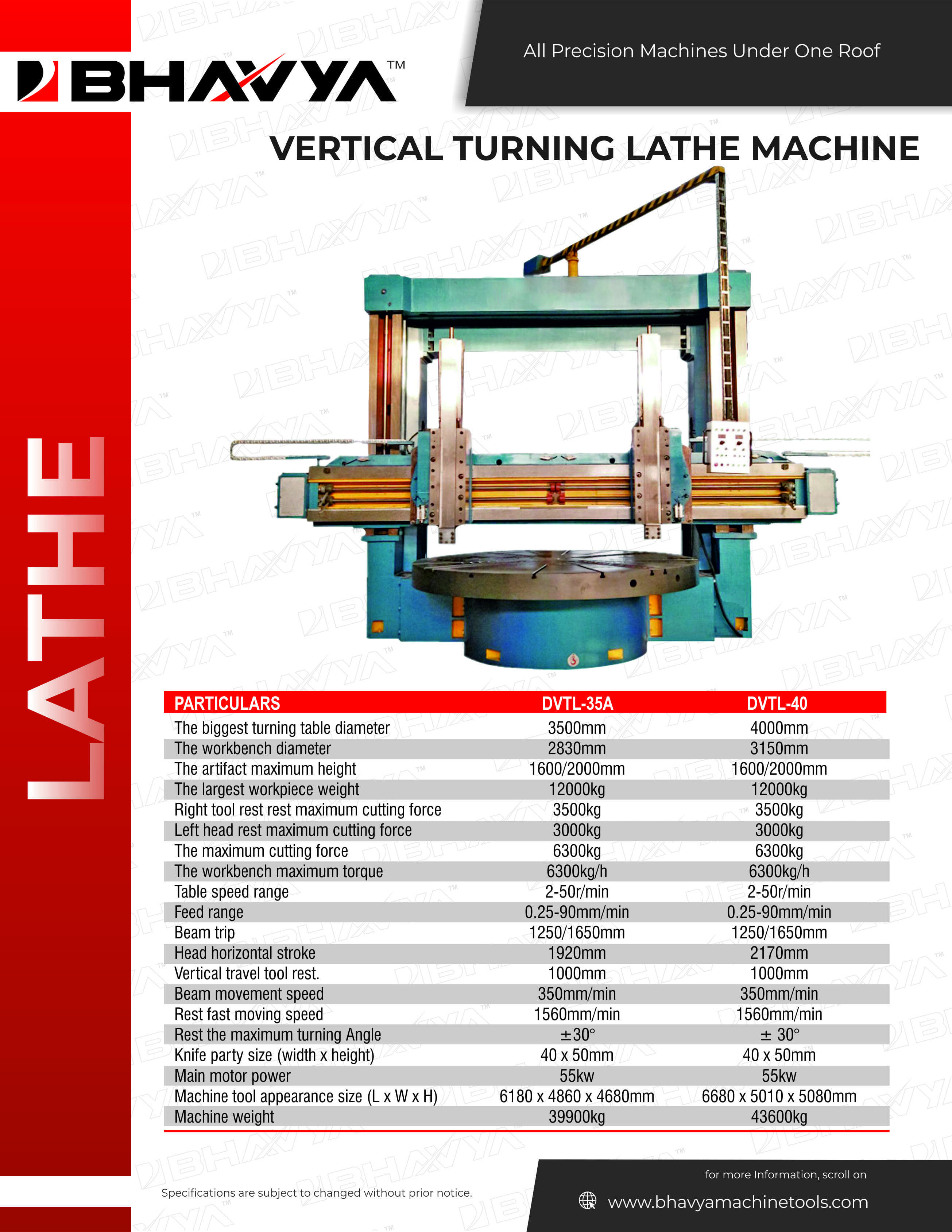

Double Column Vertical Lathe Machine

MOQ : 1 Unit

Double Column Vertical Lathe Machine Specification

- Product Type

- Vertical

- Material

- Mild Steel

- Cutting Thickness

- Up to 600 mm (Depends on tool and material) Millimeter (mm)

- Cutting Speed

- 3-40 m/min (Variable) m/s

- Automatic Grade

- Automatic, Semi-Automatic

- Control System

- PLC or CNC Control Panel

- Max. Swing Diameter

- 1600 mm to 5000 mm (Model dependent) Millimeter (mm)

- Voltage

- 220-440 Volt (v)

- Weight (kg)

- 4000-15000 kg (Depending on model) Kilograms (kg)

- Feature

- Other

- Color

- Blue

- Drive Type

- Geared/Servo Drive

- Spindle Speed Range

- 2-63 RPM (Stepless/Stepped)

- Coolant System

- Provided

- Max Turning Height

- 900 mm to 3500 mm

- Tool Post

- Two (Left & Right)

- Power Source

- Electric

- Table Diameter

- 1400 mm to 4500 mm

- Application

- Heavy industrial metal cutting and turning operations

- Bed Construction

- Box type, Heavily ribbed

- Chuck Type

- 4 Jaw Independent Chuck or Hydraulic Chuck (Optional)

- Main Motor Power

- 15 kW to 55 kW

- Lubrication

- Automatic/Manual Centralized Lubrication

Double Column Vertical Lathe Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Advance (CA)

- Supply Ability

- 10 Units Per Month

- Delivery Time

- Days

- Main Domestic Market

- All India

About Double Column Vertical Lathe Machine

Experience prodigious performance with our Double Column Vertical Lathe Machine, a meritorious solution for robust heavy-duty metal cutting. With table diameters ranging between 1400 mm and 4500 mm, and turning heights up to 3500 mm, this trending machine incorporates dual tool posts, an excellent geared/servo drive, and ephemeral yet precise speed adjustment from 2-63 RPM. The geared box type bed delivers unrivaled stability, while its automatic/manual lubrication and advanced coolant system ensure extended tool life. Optional CNC/PLC controls support modern, efficient machining. Stock ready for swift delivery across India.

Exceptional Features & Versatile Applications

This double column vertical lathe offers remarkable features such as high machining accuracy, robust construction, and easy operation. Suitable for both general and specific heavy industrial metal turning tasks, it accommodates variable cutting thickness and speeds. The machines design is tailored for continuous, reliable use in demanding settings, making it ideal for factories requiring meritorious performance. Table indexing, dual tool posts, and flexible control options enhance efficiency in large-scale or customized metalworking processes.

Prompt Delivery & Stock Availability

Serving Indias major industrial markets, our Double Column Vertical Lathe Machine is typically available for immediate shipment, ensuring stock ready for fast deployment. With express shipping options and a continuous supply chain, arrival times are minimized, allowing clients to meet production timelines effortlessly. Flexible supply ability and reliable logistics ensure your machine is delivered on schedule, whether for a single installation or nationwide manufacturing expansion projects.

Exceptional Features & Versatile Applications

This double column vertical lathe offers remarkable features such as high machining accuracy, robust construction, and easy operation. Suitable for both general and specific heavy industrial metal turning tasks, it accommodates variable cutting thickness and speeds. The machines design is tailored for continuous, reliable use in demanding settings, making it ideal for factories requiring meritorious performance. Table indexing, dual tool posts, and flexible control options enhance efficiency in large-scale or customized metalworking processes.

Prompt Delivery & Stock Availability

Serving Indias major industrial markets, our Double Column Vertical Lathe Machine is typically available for immediate shipment, ensuring stock ready for fast deployment. With express shipping options and a continuous supply chain, arrival times are minimized, allowing clients to meet production timelines effortlessly. Flexible supply ability and reliable logistics ensure your machine is delivered on schedule, whether for a single installation or nationwide manufacturing expansion projects.

FAQs of Double Column Vertical Lathe Machine:

Q: How does the dual tool post enhance the efficiency of the machine?

A: The dual tool post (left and right) allows simultaneous or sequential machining, improving productivity and minimizing changeover time during heavy-duty metal turning operations.Q: What is the process to customize the machine dimensions and features?

A: Customers can specify required dimensions and features before ordering. Our engineering team consults to ensure that table size, turning height, control systems, and drive types are tailored to your industrial needs.Q: When should I opt for the hydraulic chuck over the 4 jaw independent chuck?

A: Choose the hydraulic chuck for faster clamping and automated operations, especially when handling repetitive jobs or large-volume production. The 4 jaw independent chuck is useful for irregular-shaped workpieces and manual adjustments.Q: Where can the Double Column Vertical Lathe Machine be used most effectively?

A: This machine is ideal for shipyards, heavy machinery manufacturing, power generation sectors, and fabrication workshops that require precise and durable metal turning under continuous loads.Q: What benefits does the stepless spindle speed adjustment offer?

A: Stepless spindle speed adjustment enables precise control over cutting speeds, optimizing finish quality and tool longevity for various materials and cutting conditions.Q: How does the automatic lubrication system contribute to machine performance?

A: The automatic centralized lubrication system ensures all moving components are continuously and efficiently lubricated, reducing wear, maintenance downtime, and extending the machines operational life.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Vertical Lathe Machine Category

Single Column Vertical Lathe Machine

Minimum Order Quantity : 1 Unit

Max. Swing Diameter : 1000 mm Millimeter (mm)

Product Type : Vertical

Material : Mild Steel

Cutting Speed : 550 m/min m/s

Voltage : 220440 Volt (v)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS